Fabricated

Assemblies

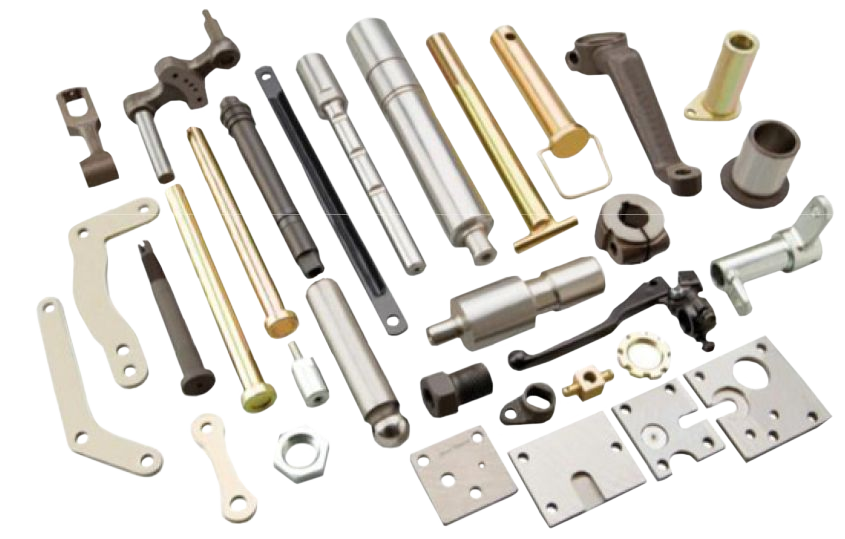

Fabricated assemblies in the automotive industry refer to components that are created by combining various metal parts

With years of specialized experience in producing Fabricated Assemblies through Robotic MIG Welding, Spot Welding, and Projection Welding. Mehta Automotive is the preferred partner for customers seeking high-quality, precision-engineered components. Our advanced MIG welding robots, deep domain expertise, and skilled robot programming team enable us to deliver assemblies that consistently exceed customer expectations. Serving both the Automotive and General Engineering sectors, we ensure structural integrity, repeatability, and cost-efficiency in every batch. Our value engineering (VA/VE) approach helps customers reduce costs without compromising on quality earning us their long-term trust for repeat orders and new product developments.

Fabricated assemblies in the automotive industry refer to components that are created by combining various metal parts, often through processes such as welding, bolting, or riveting. These assemblies are typically used in key structural and mechanical areas of a vehicle and are made to fit specific design requirements. Fabricated assemblies are crucial for providing strength, stability, and functionality in various automotive systems.

Functions of Fabricated Assemblies:

Structural Support

Durability and Strength

Integration of Multiple Components

Customization

These assemblies can be customized to fit specific design and functional requirements, allowing for flexibility in automotive manufacturing. This makes them ideal for creating unique parts for different vehicle models or custom builds.

Types of Fabricated Assemblies in Automotive:

01

Chassis Assemblies

These are large, structural parts that provide the foundation of the vehicle’s frame. The chassis must be strong enough to handle the weight of the vehicle while absorbing impacts during driving.

03

Suspension Components

02

Engine Cradle Assemblies

04

Exhaust Assemblies

Contact us

With years of specialized experience in producing Fabricated Assemblies through Robotic MIG Welding, Spot Welding, and Projection Welding. Mehta Automotive is the preferred partner for customers seeking high-quality, precision-engineered components. Our advanced MIG welding robots, deep domain expertise, and skilled robot programming team enable us to deliver assemblies that consistently exceed customer expectations. Serving both the Automotive and General Engineering sectors, we ensure structural integrity, repeatability, and cost-efficiency in every batch. Our value engineering (VA/VE) approach helps customers reduce costs without compromising on quality earning us their long-term trust for repeat orders and new product developments.

Manufacturing Processes for Fabricated Assemblies:

With advancements in welding technologies, 3D printing, and the use of high-strength, lightweight materials, automotive fabricated assemblies are becoming more efficient and sophisticated. These improvements are helping to reduce vehicle weight, increase fuel efficiency, and enhance safety while maintaining the strength and durability of essential parts.

In conclusion, fabricated assemblies are crucial in automotive manufacturing, playing a vital role in providing structural integrity, durability, and customization in various vehicle components. These assemblies ensure the smooth functioning of the vehicle while allowing for innovations in design and performance.

People + Technology

Innovative Thinking

Our continued investment in new technology is pushing us towards greater heights

Forward Thinking

Future Focused

Our continued investment in new technology is pushing us towards greater heights.

Other Products

Subscribe now

Get the latest news & updates